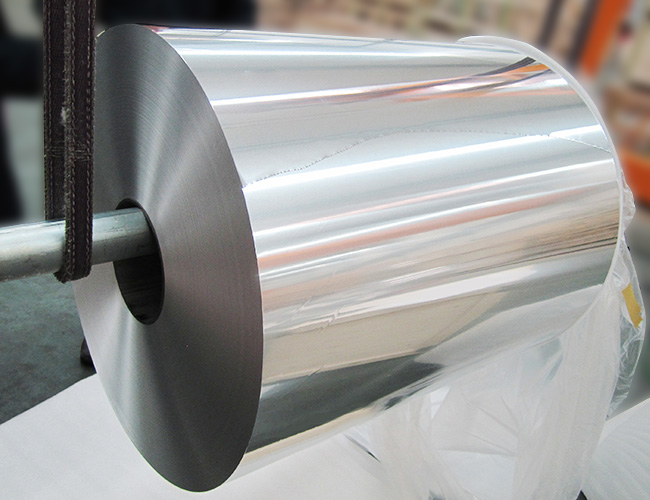

Aluminum coil is an important ingredient in the production of a wide range of industrial, commercial and consumer products. Air conditioners, automobiles, aircraft, furniture, structural components and many other products can involve the use of aluminum coil. “Aluminum coil” is the term used to describe the raw product of the aluminum sheet production process

In order to support our coil processing lines we keep a large stock range of Aluminium coils. Our grades include 3003 H14, 1050 H14, 3005 H14 and 3105 H14 material.

The coils are suited to our production line so 1000 mm or 3 foot (914 mm) wide as standard. The thickness ranges from 0.4mm up to 1.2mm with typical weights from 1 to 2 tonnes. Other alloys and tempers are available.

In addition we also offer small coils also described as Aluminium insulation coils. These have thickness between 0.3 – 2mm and width between 1000mm – 1250mm, with two different finishes: stucco or mill finish. The large range of alloys offer exceptional formability, corrosion resistance, toughness and mechanical properties to resist mechanical or thermal abuse in service. These are used, for many applications including, for refrigeration and heat insulation installers for coating boilers, pipes, ducts and other parts of the installation. These are typically produced in sizes such as 125 kgs or 150 kgs but generally produced to clients requirements.

Due to our large demand for processing we have excellent supply routes for our coils this means that if we don’t have immediate availability or enough stock we can source in around 1-4 weeks. As well as plain or smooth finish Aluminium we also keep stucco embossed coils or can supply painted or laminated. All our coils can either be reduced in weight to suit the clients processing capabilities, cut into sheet or precision slit into narrow coils. We can even convert them into corrugated sheets.

Characteristics of aluminium coil

| ALLOY NO. | TEMPER | THICKNESS(MM) | WIDTH(MM) | USAGE |

| 1050、1060 | H18 | 0.14-0.30 | 200-2600 | PS printed materials substrate etc |

| 1050、1060、1100 | O H22 | 0.15-1.50 | 20-2600 | aluminum plastic composite tube etc |

| 1060 | O | 0.20-3.0 | 100-2600 | transformer strip etc |

| 1100、1060 | O H22 | 0.20-0.50 | 100-2600 | capacitor strip etc |

| 1050、1060、1070、1100、1200 | O H12/2 H14/24 H16/26 H18 H19 | 0.20-3.0 | 15-2600 | building decoration materials, stamping products, building mirror materials, nameplate, insulation materials ,etc |

| 3003、3105 | O H12/H22 H14/24 H16/26 H18 H19 | 0.20-3.0 | 15-2600 | Washing machine cylinder body, heat exchanger, Room partition, baffle, hall board, automotive insulation board, deep drawing products, sanitary equipment parts and pipes, roof building materials, automobile license plate, etc |

| 3004、3104、 | O H12/H22 H14/24 H16/26 H18/28 H32 H36 H38 | 0.20-3.0 | 15-2600 | all aluminum pop-top cans body ,all sorts of lamps and lanterns parts, automobile chassis, the television lagging, etc |

| 3005、3003 | H14 H16 | 0.20-3.0 | 15-2600 | Cell lithium battery shell, etc |

| 4343/4004/4343 | O H14 H24 H18 | 0.20-3.0 | 20-2200 | Brazing composite materials etc |

| 5005、5052、5082、5083、5182 | O H111 H12 H14 H16 H18 H22 H32 H24 H34 H26 H36 H38 H112 | 0.20-3.0 | 20-2600 | Washing machine cylinder body, tanks, all aluminum POP cans, lid, pull ring, Marine equipment and materials, railway tank truck, Marine equipment and materials ship accessories, instruments materials brazing composite materials etc |

| 6061,6063,6082 | T4,T5,T6 | 0.10-3.5 | 50-2600 | Automobile, stamping parts,equipment |

| 8011 | H14 H24 H16 H26 | 0.14-0.30 | 200-2600 |